blog

From cultivation to enjoyment

From cultivation to enjoyment

1. Cultivation

The coffee fruit comes from trees of the genus Cafea. To date, 124 species have been identified, of which only Arabica and Robusta are grown for commercial purposes. The coffee tree grows in about 70 countries near the equatorial zone and requires a tropical climate and high altitude, which determine the quality and taste of the coffee. The 'coffee bean' is the seed of the coffee tree, which turns red when ripe and reaches the size of a cherry.

2. Arabica or Robusta

Arabica coffee is smooth and aromatic, and accounts for 70% of the world's production. These coffee trees grow at high altitudes and are very sensitive to climatic conditions. The remaining 30% of world production is made up of the Robusta variety, whose beans are much more robust and contain almost twice as much caffeine as Arabica beans.

3. Harvest

No matter what time of the year it is, there is always a harvest of Arabica and Robusta somewhere on the planet. A healthy coffee tree produces between 1 and 5 kilos of fruit per season. To produce 1 kg of coffee beans, we need about 5 to 6 kg of fruit, which is harvested either by hand or mechanically, using special vehicles.

4. Processing

In order to isolate the green beans, the coffee cherries must be processed, a process that must be done with great care to avoid damaging the fruit. The coffee berries have a sweeter taste when they are ripe, and the processing must be done within a few hours of harvesting in order to preserve their quality.

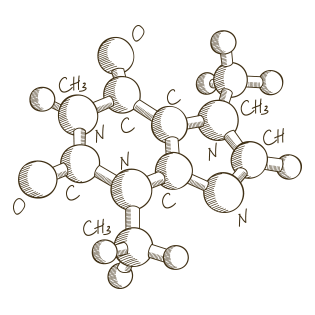

5. Decaffeination

Caffeine is an odourless, slightly bitter substance. In its natural form in coffee, it is a natural stimulant that, once consumed, has an immediate effect on the central nervous system, and is just as quickly eliminated from the body. The method of removing the caffeine from the green coffee beans before roasting is called decaffeination.

6. Roasting

It is considered the most important stage and requires talent from the coffee maker. By roasting, the beans change shape and size, giving off aroma. In the first few minutes, the coffee turns yellow and the water in the beans evaporates. Soon the first 'crack' of the bean bursting is heard and is an acoustic 'clue', together with the appearance and aroma of the beans, to the roasting stage. A second 'crack' is heard 3 to 5 minutes later, when the process is complete.

7. Perfumery

The flavouring process takes place 4 to 5 days after roasting, so that the grains have had time to eliminate the carbon dioxide they continue to produce. These are vegetable flavourings, which are based on oils or alcohol. The aromatic liquids are mixed and coated on the roasted beans. The aromas are released and further enhanced when the coffee is ground and brewed.

8. Production of Instant Coffee

The production of instant coffee follows all the processing stages up to the grinding stage, where different varieties of roasted coffee are combined to make a blend, which is ground and combined with hot water, creating a huge cup of coffee. The resulting mixture is filtered to remove all insoluble particles. The moisture in the mixture is then gradually removed with hot or cold air, creating the final instant coffee powder.

9. Blending

A blend is a mixture of coffee beans from different varieties, while single-origin coffee is coffee that comes from a country, a cooperative or a farm. Blending combines characteristics from different coffees to create the "ideal" cup. In the industrial sector, the ingredients and proportions in blends are secrets that are "well kept", and the packaging does not indicate the type or origin of the beans.

10. Packaging & Handling

The enemies of coffee are oxygen, heat, light, humidity and strong odours. From roasting to disposal, no more than 15 days should elapse. At Loumidi Coffee Roasters, all coffees are sealed in protective atmosphere packaging, with a special valve that allows carbon dioxide to escape without oxygen entering. Thus, the coffee is kept truly unaltered, aromatic and fresh for up to 12 months.

11. Grinding

The purpose of grinding is to crush the beans so that the water extracts the maximum amount of the coffee's substances. For each type of coffee, a corresponding grinding machine is used. The quality of the grinding process directly affects the quality of the coffee, so it is essential that the grinder is properly operated, adjusted and maintained. Once purchased, the coffee must be stored in an airtight container in a cool, dry and dark place, away from strong odours, for up to two weeks from the day of grinding.

12. Production

A cup of coffee consists of 98% to 99% water, the quality of which plays an important role in the taste: the water should be clear and not smelly. The combination of minerals, salts and metals that can affect the beverage can be perceived either by eye or by taste. Quality also depends on the quality and freshness of the beans, the grinding, the machine and the cup or mug.

13. The Ideal Coffee Cup

In the coffee industry, the method of taste testing is used to check the quality of the beans. The coffee is graded from 0 to 100, based on its taste characteristics and the number of defects. The cupping process is an integral part of the chain: the evaluation of the aroma of the freshly ground coffee, the body, the taste, the aroma in the cup and the aftertaste are the characteristics that define the 'personality' of the coffee.